HAWN operates a heat generation plant in the Schenefeld town centre - EKZ, which supplies the shopping centre and the western heating network with heat.

Modernising and increasing the efficiency of the heat generation system

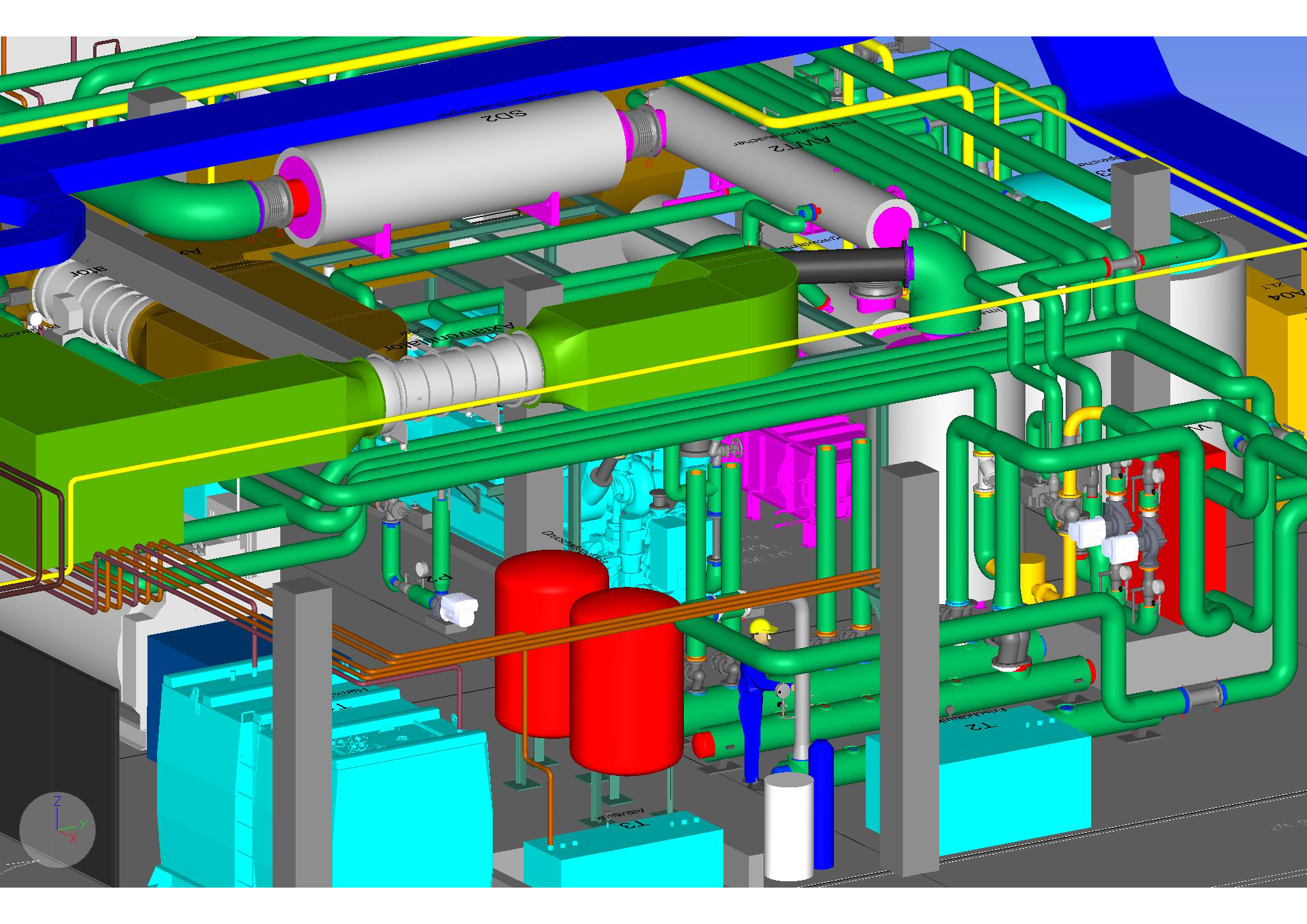

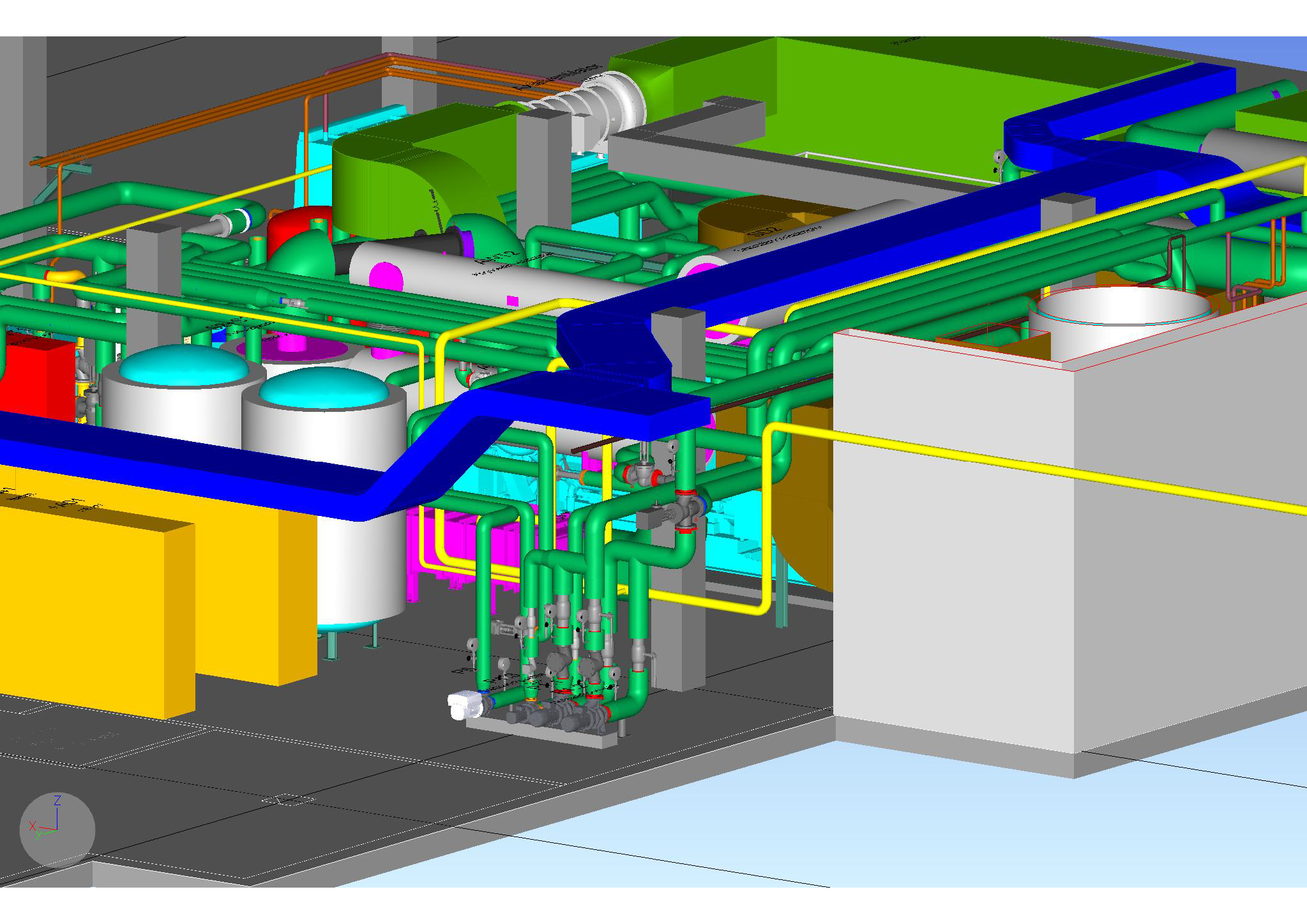

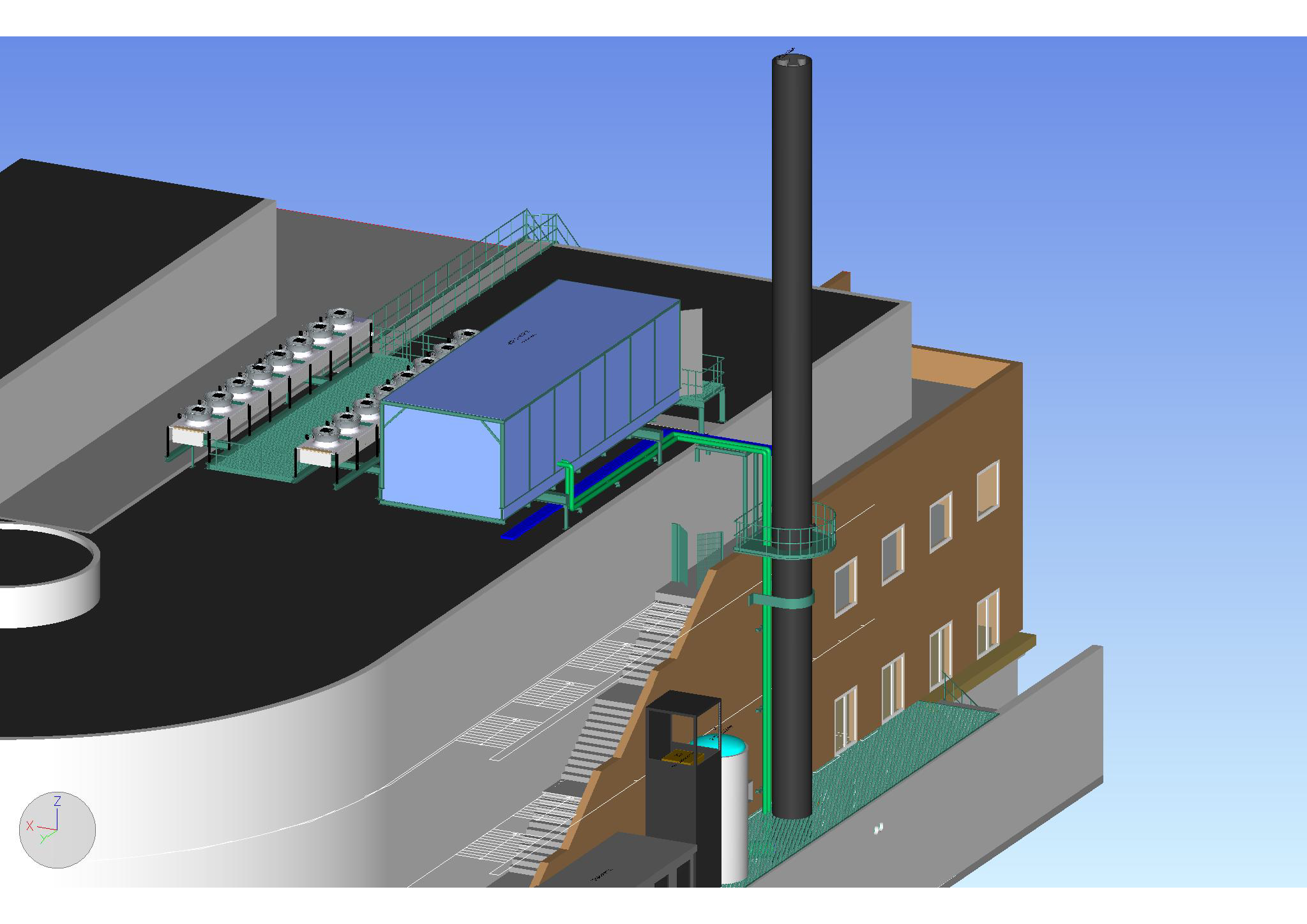

The existing system, consisting of three low-temperature natural gas boilers, is in need of modernisation and will be replaced by a state-of-the-art I-CHP system (innovative combined heat and power generation) and a new low-temperature natural gas boiler. The new CHP module (combined heat and power unit) will generate both electrical and thermal energy. Additional heat is provided by a gas boiler, an electric boiler and a heat pump. These components will be installed in the existing boiler room in the basement of the shopping centre.

Focus on sustainability and energy efficiency

The thermal energy generated is either used directly in the shopping centre or fed into the existing district heating network. The electricity generated is fed into the grid of the grid operator and recorded accordingly. A new medium-voltage station with transformer and medium-voltage switchgear will be installed outdoors to cover the power requirements of the system and subsystems.

Flexible heat supply for the shopping centre

The shopping centre's heating network is preferably supplied with heat from the heat pump. If the heat pump's output is insufficient or operating conditions are unfavourable, additional heat can be drawn from the other heat generators or HAWN's western heating network. The gas boiler serves as a backup. All heat generators are hydraulically connected to each other and connected to the heat network. A heat exchanger hydraulically separates the shopping centre network from the interconnected network.

Efficient storage and utilisation of heat

A 25m³ and two 5m³ heat storage tanks are integrated into the system to optimise the operating times and controllability of the heat pump and CHP unit. This ensures even and efficient utilisation of the heat generated.

Project period and implementation planning

ETABO is responsible for the implementation planning as well as the procurement, delivery, installation and commissioning of the main components and the EI&C package. The work will be carried out from August 2024 to around Q3 2025.

Our project team has already started work, the first major components such as the heat pump from Arctos, the gas boiler from Bosch and the electric boiler from ELWA have been awarded and engineering has begun.

Do you have any questions? Then please get in touch with your contacts at ETABO System Projects/Piping division :

Torsten Hagedorn (

|

|

|