Torsten Hagedorn and Stefan Erkelenz also asked themselves this question when we received an enquiry from EnBW entitled ‘Neckardüker HLB Rohrleitungsbau FW + Gas’. And first of all: this project is definitely a challenge!

But what exactly is a “Düker”? According to Wikipedia, the term comes from Low German or Dutch and means ‘diver’. A Düker (in English: culvert) is a structure that channels water past an obstacle or to a subterranean waterway. Typically embedded so as to be surrounded by soil, a culvert may be made from a pipe, reinforced concrete or other material. Culverts come in many sizes and shapes including round, elliptical, flat-bottomed, open-bottomed, pear-shaped, and box-like constructions. The culvert type and shape selection is based on a number of factors including requirements for hydraulic performance, limitations on upstream water surface elevation, and roadway embankment height.

Our project manager and calculator Ulfert T., who can look back on many years of experience in plant construction, brings valuable expertise in culvert systems. Thanks to his expertise and our dedication, we were awarded the contract for this exciting project by EnBW.

The details of the project:

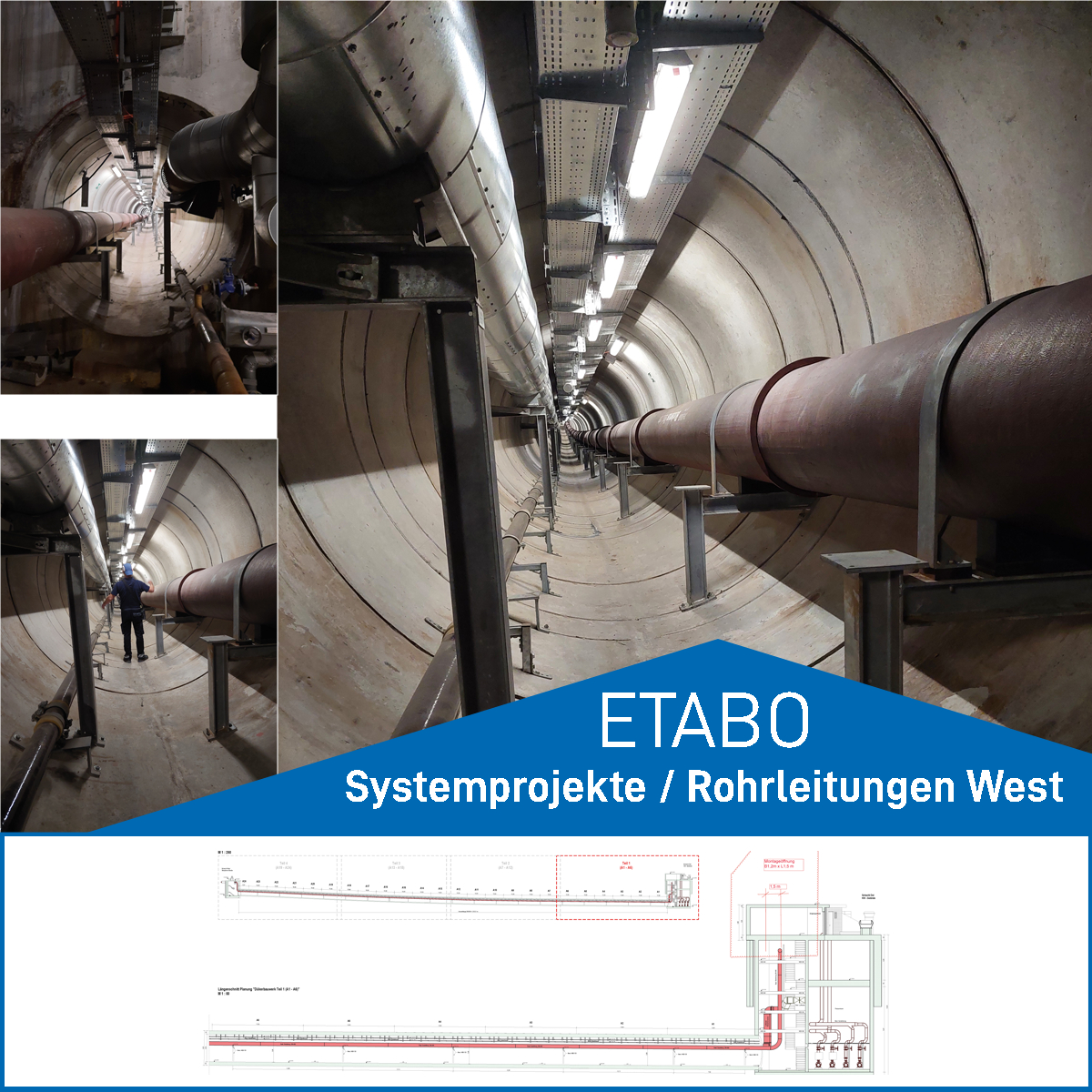

We will first dismantle old pipes by the end of February 2025 and then lay around 1 kilometre of new pipelines with a diameter of up to DN400 for district heating and gas under the Neckar in Heilbronn. These pipes will be installed in the culvert structure, which lies deep under the riverbed.

What looks very unspectacular on the isometric drawings is a considerable challenge in practice: all the material and equipment has to be lowered through a narrow opening measuring just 1.2 x 1.5 metres to a depth of 17 metres. From there, everything is brought into the approximately 240 metre long tube with a diameter of only 3 metres and welded on site. Precise planning, a smooth process and a well thought-out assembly concept are crucial here.

A particularly important aspect of this project is ensuring proper ventilation and occupational safety. In confined spaces like these, a sufficient supply of fresh air is crucial to ensure the health and safety of our employees.

We are very much looking forward to this challenging project and to a trusting, cooperative partnership with EnBW. The planning and execution of such a complex project requires not only technical expertise, but also close coordination between all parties involved.

Do you also have a challenging project and are looking for a reliable partner? Do not hesitate to contact us - we will be happy to talk to you at any time!

Torsten Hagedorn (

|

|

|

|

||